A SIMPLE but highly efficient three pack N.D.T System, Suitable for checking welds and stressed machine parts for cracks and flaws, before and after welding or machining.

The Dye-penetrant method of inspection with flaw test system may be used on materials such as Aluminum, Magnesium, Brass, Copper, Cast Iron, Steel, Stainless Steel,, Titanium, Nickel, Carbides, Stellite, and Ceramic.

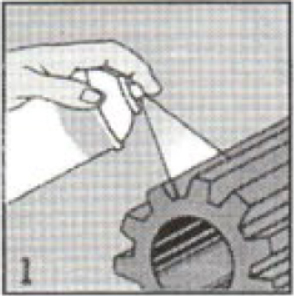

1. Pre-Clean inspection area with CLEANER SC-30 to remove oil, grease or with wire brush to remove Scale, rust for easier penetration.

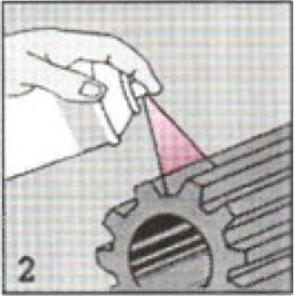

2. Spray or brush with PENETRANT SC-10, allow penetration time as per table below. Area coverage 50 sq mts/lit. approx.

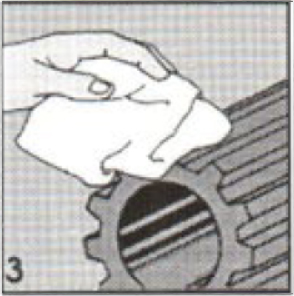

3. Wipe surface clear, using cloth soaked in CLEANER SC-30. Taking care penetrant from defect.

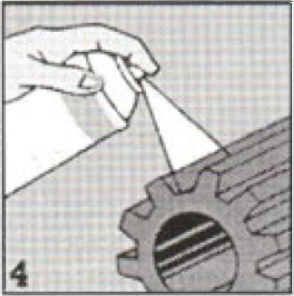

4. Shake the Aerosol can vigorously spray DEVELOPER SC-20 in thin, uniform film, from distance of 8 to 12 inches and 6 to 8 sections at a time Allow to dry. Area coverage 25 sq mts/lit. approx.

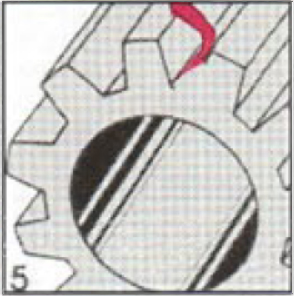

5. The vived red color combined action results in sharply defined flaw indication.

| Minimum Penetration Time for Penetrants, for parts having Temperature of 15° C to 35° C | |

| Material | Penetration Time (MIN) |

| Aluminum | 5 to 10 |

| Magnesium | 5 to 10 |

| Brass | |

| Bronze | |

| Steel | 10 to 20 |

| Carbide Tip Tools | 5 to 15 |

| Titanium and High Temp. Alloys | 20 |

| Aviation | Boilers | Nuclear |

| Automotive Plants | Tubes | Ships |

| Pressure vessels | Railways | Chemical Vessels |

| Castings | Forging | Pipelines |

Packaging: 280ml Aerosol Can, 1 ltr. Bottle, 5 ltr. Carboy

©Copyright 2020 Rajiv Machine Tools. Developed by Kadri Consultancy.